Automatic Tool Changers

Automatic Tool Changer (or ATC) press brakes are making machine setup and tool changeover faster, more reliable and a lot more efficient compared to a manual tool change process. These systems also free up time for operators to perform other tasks or get material blanks ready for bending, so production can start as soon as the tool change process is complete.

Overview

The Automatic Tool Changer is incorporated into the design of the press brake or as a separate integrated module. While designs and functionality vary and are unique to individual manufacturers, ATC press brakes generally comprise the same basic elements.

This begins with a tool storage area, either contained within the machine footprint or attached externally, a motorised system that transfers the tools between the storage area and the machine tool holders and finally, a mechanism that sets the position and spacing of the tools along the length of the machine.

The automatic tool change process is managed by the CNC system in conjunction with the bend program.

The ATC first removes any punches and dies that are not needed for the next setup and returns them to the storage area. The ATC then identifies the next set of tools that are defined in the bend program and retrieves the required punches and dies from the storage area and inserts them into the tool holders, which would generally encompass a hydraulic or pneumatic tool clamping system.

The horizontal placement of the punches and dies along the length of the machine is adjusted, including any necessary spacing between tools that is needed for part production such as box bending, where the correct tool gaps are required to accommodate part side flanges.

Automated Workflow

Automated workflow also plays a significant part in streamlining production processes with networked machines that are more effectively managed from the office to further eliminate operator intervention in the workshop. A complete working shift of scheduled bend programs and tooling setups can be remotely transferred to the machine in advance so the next automatic tool change can commence as soon as the current job is finished.

Operator Safety

Press brake users are also looking to automatic tool change as a solution for reducing operator fatigue and improving safety to minimise the risk of both short and long-term injuries. Many machines use heavy sections of tooling that require manual lifting by the operator or the use of lifting aids such as hoists to transfer tools to and from the machine. Injuries can result from lifting strain, or the tools being dropped and there are possible long-term health implications from repeated lifting of heavy tooling over the course of many years.

| ATC Benefits |

|---|

|

LVD ToolCell

ToolCell ends the search for tooling with unique stadium style storage of top and bottom tooling that is located under the machine’s back-gauge, taking advantage of the available space. The tooling stadium holds up to two complete lengths of punches and five complete lengths of dies for flexibility and space-saving all in one compact design. The ToolCell tool storage system offers a flexible tooling configuration to suit specific application requirements.

Find out moreTRUMPF ToolMaster

TRUMPF ToolMaster boosts productivity by automatically switching between bending tools. The new generation ToolMaster can accommodate three times the tool metres as the previous model and changes a tool in just a few seconds. Users can insert both standard tools as well as ACB sensor tools and customer-specific special tools.

Find out morePrima Power eP Genius

Prima Power’s bending solution, the eP Genius 1030, consists of the integration of a servo-electric press brake eP-1030 with an automatic tool change storage system.

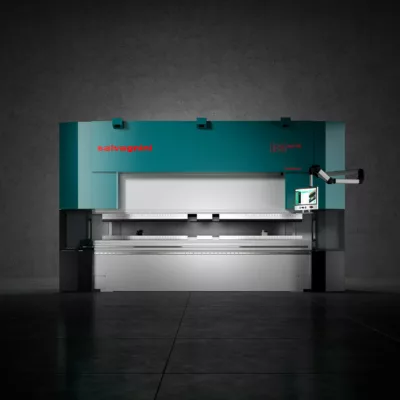

Find out moreSalvagnini B3.AU-TO

Salvagnini’s AU-TO automatic tool change device prepares the machine maximizing the potential of the automatic tool set-up and applying the best strategies on the basis of the production flow.

Find out moreWarcom BEND-MASTER

The Warcom BEND-MASTER automatic tool change solution complements its entire bending system for greater flexibility, speed, and reliability.

Find out moreVICLA ATC

VICLA ATC system is a modern and cutting-edge solution that ensures exceptional performance over time.

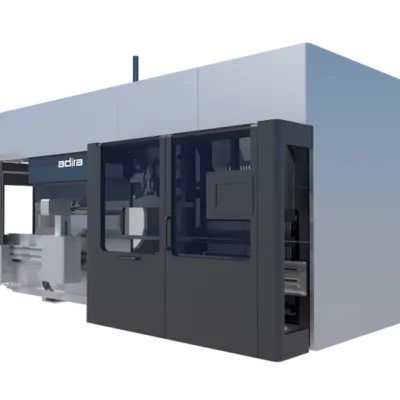

Find out moreADIRA Automatic Tool Changer BB + ATC

The automatic tool changer solution is an innovative device designed to allow tools (upper and lower) to be changed automatically, saving time, and increasing efficiency.

Find out moreVimercati VSB

The VSB solution makes bending more versatile, faster and more reliable. It eliminates the manual configuration of the machine and allows the operator to dedicate their time and skills to the preparation of the bending batches.

Find out more