LVD ToolCell

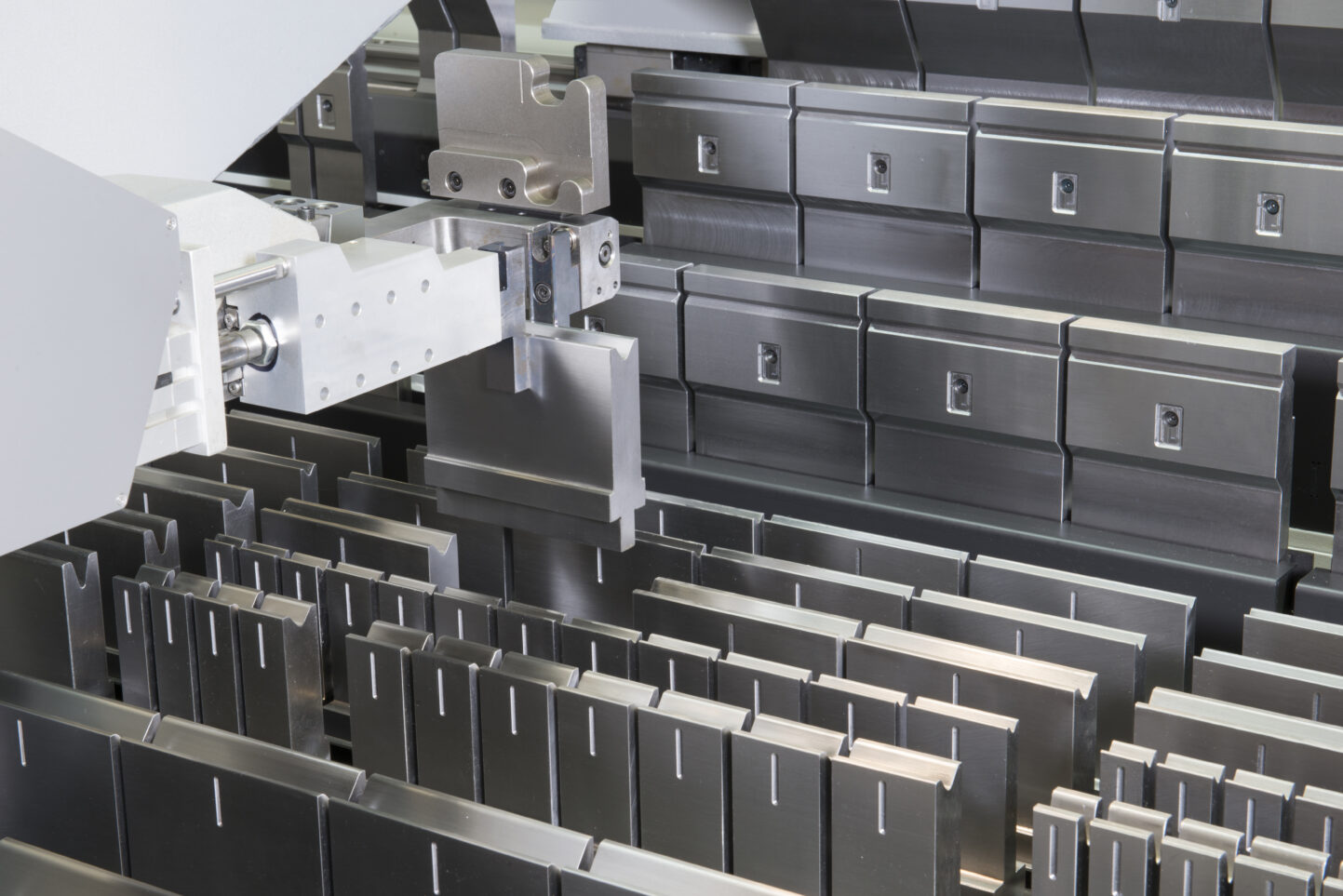

ToolCell ends the search for tooling with unique stadium style storage of top and bottom tooling that is located under the machine’s back-gauge, taking advantage of the available space.

Visit the Showroom Enquire now

The tooling stadium holds up to two complete lengths of punches and five complete lengths of dies for flexibility and space-saving all in one compact design. The ToolCell tool storage system offers a flexible tooling configuration to suit specific application requirements.

Innovative grippers built into the machine’s back gauge fingers serve as the tool changer mechanism to transfer punches and dies. While the operator is preparing parts for the next job, the machine unloads the previous tool setup and loads the next setup, all without manual intervention.

ToolCell

The ToolCell comes equipped with LVD’s patented Easy-Form® Laser (EFL) adaptive bending system. EFL ensures the first bend is accurate every time. The EFL system transmits the digital information in real time to the CNC control unit, which processes it and immediately adjusts the position of the ram/punch to achieve the correct angle. The bending process is not interrupted, and no production time is lost.

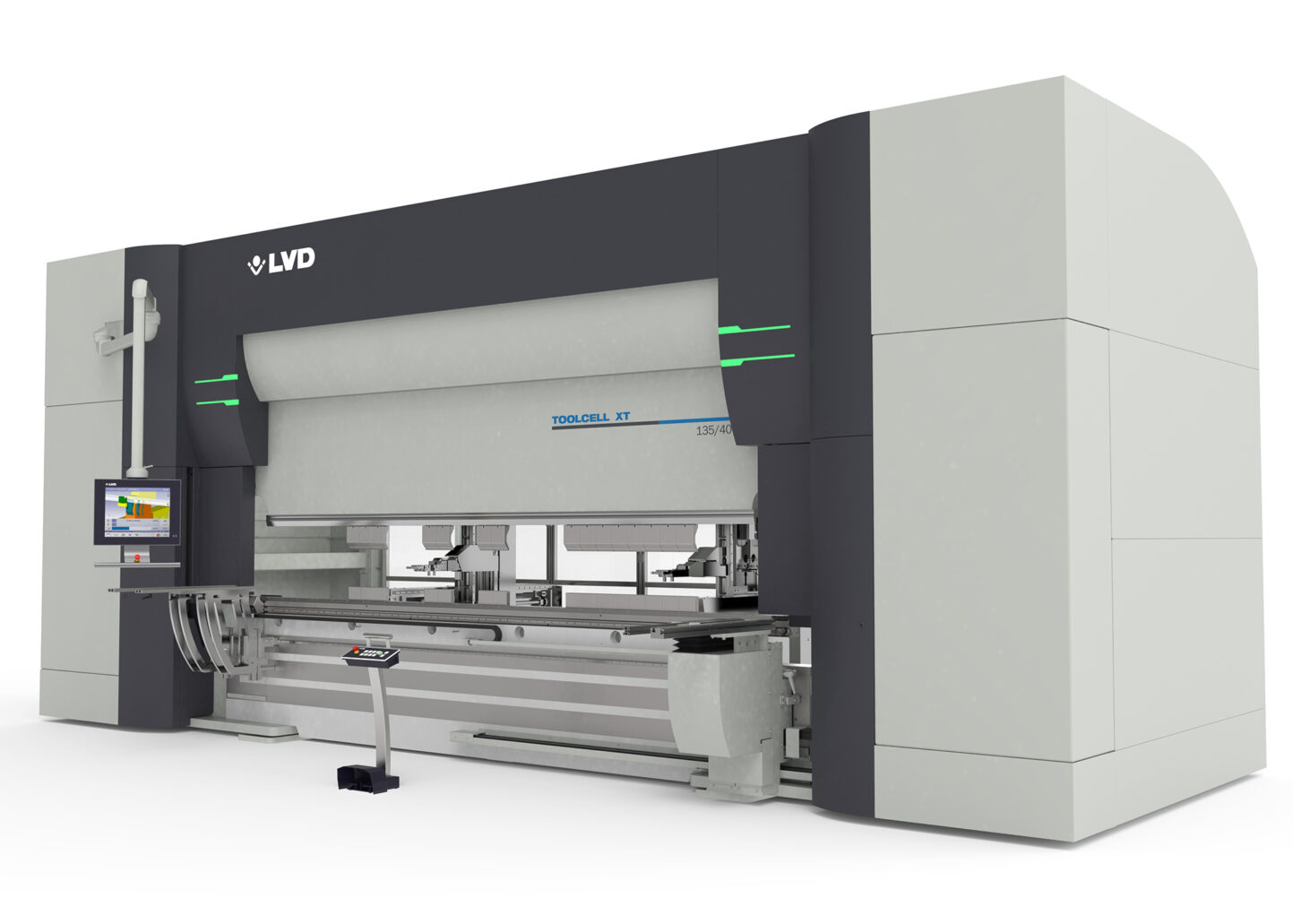

LVD also offers ToolCell XT, the latest generation of its ToolCell automatic tool changing press brake with extended capacity to hold 50 percent more tooling than the original design.

The large capacity of tools housed within the press brake provides the flexibility to handle a wider range of bending jobs, including complex layouts. With its extended tooling capacity, ToolCell XT offers the versatility to handle varying material types, organise tooling by material type, easily switch between stainless steel and mild steel applications.

ToolCell XT

Contact LVD

For more information about LVD press brakes, visit www.lvdgroup.com or contact LVD at Tel. +32 56 43 05 11, E-mail: marketing@lvdgroup.com. Find your local LVD representative at www.lvdgroup.com.