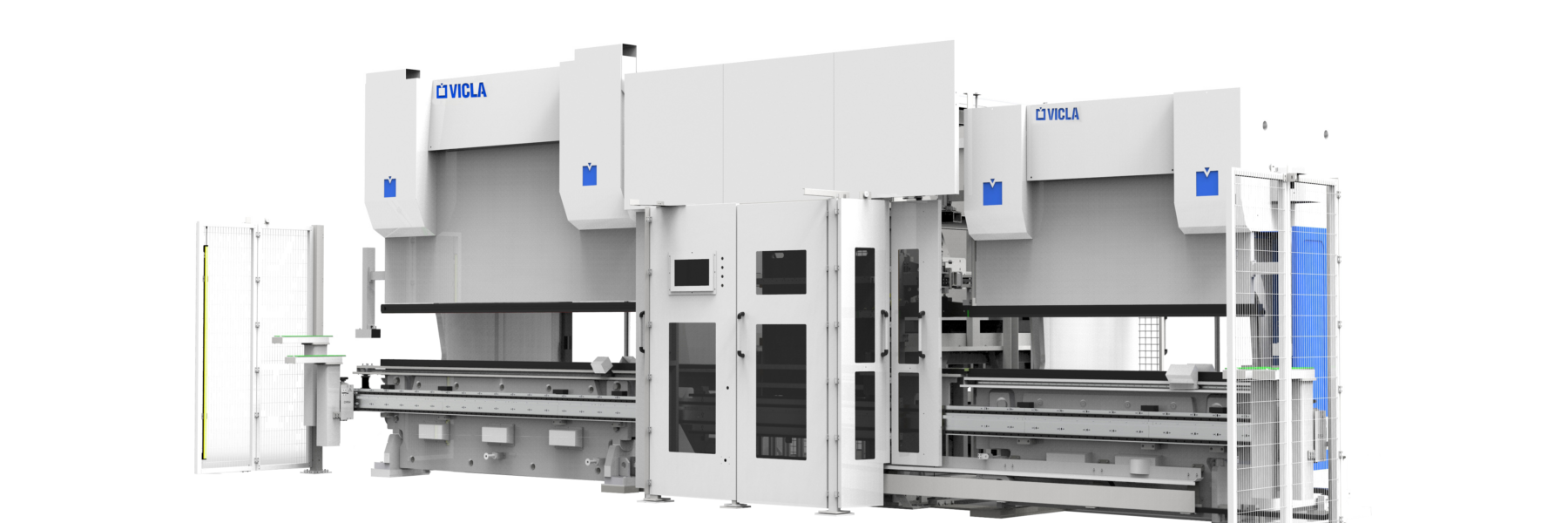

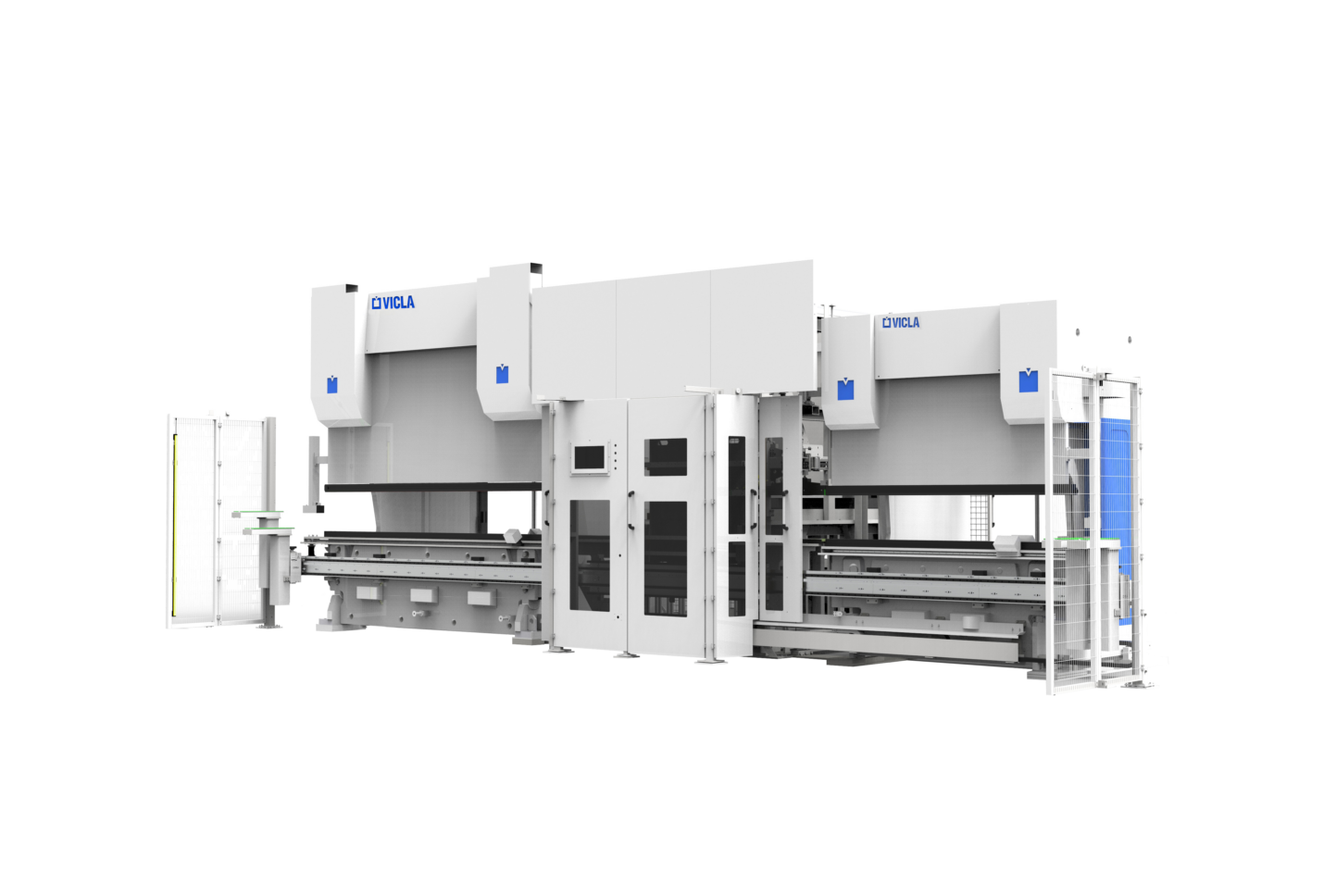

VICLA ATC

VICLA ATC system is a modern and cutting-edge solution that ensures exceptional performance over time.

Visit the Showroom Enquire now

The demand for smaller, more complex, and heterogeneous batches requires finding solutions to shorten production times and lower costs. The smaller the batch, the more the setup times impact on the productivity of the machine and on the production cost.

VICLA ATC system - Single or Twin – is designed to automate and speed-up the setups for efficiently producing small batch sizes. The system combines one or two hybrid press brakes with an automatic tool changer, allowing for multiple tooling setups, reducing setup times by 4 or 5 times compared to the ordinary manual operation.

VICLA ATC

The main element of the system is a compact shuttle that serves as robotic tool changer that places the tool sets, up to 1-3/4” V opening, in the clamping systems of the upper and lower beams. This shuttle retrieves and replaces tools in the tool magazine, which can store up to 197 ft. of dies and punches. The tooling can be used in manual or robotic setups. The upper tools can also be rotated 180 degrees.

A modular and custom-made solution

One of the many advantages of the VICLA automatic tool changer is the offline programming capability. The CAD / CAM system processes the three-dimensional file, creates the best bending sequence and sends the program to the machine, which is automatically equipped, and calls-up the bending sequence directly on the numerical control screen.

All tooling and processing data are automatically saved at the end of the job and exported to the management system for data analysis.

Contact VICLA

For more information visit www.vicla.eu